As Singapore progresses towards cleaner and more sustainable energy, solar photovoltaic (PV) systems have become a proven and reliable solution for property owners seeking long-term energy savings. At First Solution Group, we design, supply, install, and maintain high-performance grid-connected PV systems built to local EMA, SP Group, and WSH standards. Our systems are engineered for optimal yield, minimal maintenance, and full compliance with the latest Fire Code and SS 638 electrical standards. The following sections outline our complete scope of works, including design, installation, testing, and maintenance procedures. Each process is executed by certified engineers and Licensed Electrical Workers (LEW PV) to ensure safety, reliability, and performance excellence.

1.0 Design, Verification & Documentation

1.1 System Design and Configuration

The design phase begins with a comprehensive technical assessment of the site’s structure, orientation, and shading profile. Using advanced PV simulation software, our engineers calculate expected energy output, inverter loading, and array efficiency under Singapore’s tropical climate. Each layout is optimised to achieve the best balance between module performance, roof geometry, and solar panel system cost. Electrical single-line diagrams are developed to illustrate DC and AC configurations, including isolators and protection devices. Every design complies with EMA’s Technical Requirements for Interfacing Solar Photovoltaic Systems to the Grid and relevant SS 638 standards.

1.2 Engineering Drawings and Documentation

During this stage, detailed shop drawings and as-built documentation are prepared for client review and regulatory submission. The drawings include PV array layouts, cable routing plans, earthing connections, and inverter placement diagrams. All documents undergo internal verification to ensure technical accuracy and compliance with the approved design intent. These verified drawings serve as the foundation for construction, inspection, and future maintenance works. A complete documentation package—including structural calculations, load assessments, and safety method statements—is maintained throughout the project for audit and quality assurance purposes.

1.3 Performance Modelling and Simulation

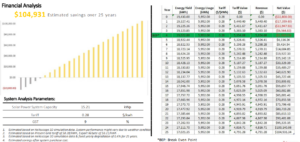

To validate system efficiency, we perform full-scale simulations using software such as PVsyst or equivalent modelling platforms. This process estimates annual energy yield, system losses, and expected performance ratios based on real irradiance data from the Singapore Meteorological Service. The simulation results guide decisions on inverter sizing, cable runs, and tilt angles to maximise generation output. Any deviation between simulated and measured data is analysed to fine-tune the final design. This proactive modelling approach ensures each system achieves consistent, predictable returns over its 25-year lifespan.

1.4 Safety and Quality Documentation

First Solution Group maintains strict documentation control throughout all design and construction stages. We prepare risk assessments, method statements, and Safe Work Procedures (SWP) in compliance with bizSAFE Star and ISO 9001 standards. These documents outline work sequencing, fall-protection methods, and safe electrical practices to protect both personnel and property. Each project is assigned a Safety Officer responsible for toolbox briefings and site safety audits. Our commitment to transparent documentation ensures full traceability and readiness for SCDF or EMA inspections at any time.

2.0 Supply & Installation

2.1 PV Modules and Mounting Structures

First Solution Group supplies Tier-1 monocrystalline PV modules certified to IEC 61215 and IEC 61730 standards, ensuring proven reliability under high-temperature and humidity conditions. The mounting structures are fabricated from marine-grade aluminium or galvanised steel, designed to withstand Singapore’s wind loading requirements under Eurocode 3. All structural components are corrosion-resistant and anchored to the roof using approved non-penetrative or clamp-type fixtures where possible. Our installation team ensures uniform alignment, secure grounding, and proper cable management for long-term durability. Every completed array undergoes structural verification before electrical interconnection.

2.2 Inverter and Data Logging System

We install grid-tied string inverters or central inverters, selected based on project capacity and roof segmentation. Each inverter is EMA-approved and equipped with anti-islanding protection to ensure safe operation when interfacing with SP Group’s grid. The inverters are mounted at shaded and well-ventilated locations provided by the client to maintain optimal operating temperature. Integrated data-logging functions record real-time performance and fault events, allowing remote monitoring through secure cloud platforms. This enables early detection of abnormalities and continuous performance optimisation throughout the system’s life cycle.

2.3 Balance of System (BOS) Components

The Balance of System (BOS) includes DC cabling, AC trunking, isolators, junction boxes, surge protection devices, and main circuit breakers. All electrical components are rated for outdoor service and comply with SS 638 and IEC 60364 installation standards. Our technicians ensure proper cable sizing to minimise voltage drop and maintain system efficiency across DC and AC circuits. The PV output is safely reticulated to the Main Switchboard (MSB) via the Point of Common Coupling (PCC), enabling seamless integration with existing building electrical infrastructure. Clear circuit labelling and identification tags are applied for maintenance traceability and future system expansion.

2.4 Lightning and Earthing Integration

To ensure full electrical protection, the PV system is bonded to the building’s lightning protection network following SS 555:2018 and SCDF Fire Code guidelines. Surge protection devices are installed on both DC and AC sides to safeguard inverters and modules from transient over-voltages. All metallic frames and mounting rails are connected to the common earthing network to prevent potential differences. A dedicated test link is provided for routine earth-resistance measurements and inspection by certified personnel. This integrated protection system reduces downtime risks and enhances long-term operational safety.

3.0 Testing & Commissioning

3.1 System Testing and Quality Assurance

Upon completion of installation, comprehensive testing and quality checks are performed before the system is energised. Electrical tests include insulation resistance, polarity verification, string-level current measurement, and inverter functional testing. The system’s measured output is compared with simulation benchmarks to ensure compliance with design expectations. Only qualified engineers and Licensed Electrical Workers carry out these tests, ensuring all results are traceable and documented. Any anomalies identified are rectified before formal commissioning begins to guarantee safe and efficient operation.

3.2 LEW Endorsement and Submission

A Licensed Electrical Worker (LEW PV) endorses the completed installation, verifying that all electrical connections, earthing points, and protection devices meet regulatory standards. The LEW prepares and submits all necessary documents to SP Group and EMA for grid-connection approval. This process includes the submission of single-line diagrams, test reports, and interconnection schematics for official endorsement. The LEW also supervises live testing to confirm grid synchronisation and system stability. Once approval is obtained, the PV system is officially energised and connected to the building’s main power supply.

3.3 Performance Verification and Handover

After commissioning, a detailed performance verification is carried out to validate generation output under normal operating conditions. The commissioning team records inverter efficiency, voltage stability, and output power factor for baseline performance data. A comprehensive handover package—including as-built drawings, equipment warranties, operation manuals, and test certificates—is presented to the client. This ensures the building owner receives full documentation for future audits, maintenance, and warranty claims. With system performance validated and safety confirmed, the installation enters the Defects Liability Period (DLP) under First Solution Group’s maintenance supervision.

4.0 Operation & Maintenance (O&M)

4.1 Operation & Maintenance During Defects Liability Period (DLP)

Once the system has been successfully commissioned and energised, First Solution Group provides complete Operation and Maintenance (O&M) support during the Defects Liability Period (DLP). The DLP typically spans twelve to twenty-four months, during which all system components are monitored to ensure stable operation. Our maintenance team tracks real-time performance data to identify irregularities before they affect energy generation. Preventive maintenance and prompt corrective actions are conducted whenever necessary to ensure optimal uptime. This proactive monitoring framework safeguards the client’s investment and ensures compliance with manufacturer warranties.

4.2 Cloud-Based Monitoring Platform

All PV systems installed by First Solution Group are equipped with cloud-based monitoring systems that provide continuous visibility into energy production and equipment status. The platform generates automatic alerts for underperformance, inverter faults, or power interruptions, allowing remote diagnostics by our engineers. Clients can access performance dashboards that display daily, monthly, and cumulative generation data. This ensures transparency and helps facility managers compare actual yield with predicted performance ratios. The integrated monitoring system forms a key component of our smart maintenance ecosystem, reducing downtime and improving long-term reliability.

4.3 Bi-Annual Performance Reporting

To ensure accountability and consistent communication, our engineers prepare bi-annual performance reports throughout the DLP period. Each report summarises energy generation trends, inverter efficiency, and any corrective maintenance activities carried out. Performance metrics are benchmarked against the original PV simulation to identify potential losses due to shading, soiling, or component degradation. Any performance deviation beyond the acceptable threshold is promptly investigated and rectified. These reports not only provide clients with performance assurance but also serve as documentation for warranty validation and future audits.

4.4 Preventive Maintenance and Site Inspection

As part of our scheduled maintenance programme, preventive site inspections are conducted annually to maintain optimal system health. The inspection covers mechanical, structural, and electrical components, including tightening of connections, inspection of mounting bolts, and visual checks for corrosion or damage. Electrical measurements such as voltage, current, and insulation resistance are recorded to verify system integrity. In addition, thermal scanning is performed to detect hot spots or irregular heat signatures in PV modules and cable joints. These preventive measures extend system lifespan and ensure consistent energy output throughout the operational years.

4.5 PV Module Cleaning and General Servicing

To maintain energy yield, periodic cleaning of the PV modules is performed using soft brushes and water, without harsh chemicals that could damage module coatings. Spot cleaning is typically carried out once or twice annually depending on dust accumulation and local conditions. Clean modules enhance sunlight absorption and maintain system efficiency close to the design specification. During servicing, the team also inspects inverter fans, junction boxes, and lightning arrestors for any signs of wear or malfunction. All maintenance records are digitally logged and shared with clients for transparency and tracking.

5.0 Client Responsibilities

5.1 Site Preparation and Access

Clients are responsible for ensuring that safe roof access and lifting facilities are available for installation and maintenance works. The site should include designated shaded areas for mounting inverters, DC combiner boxes, and PV-ACDB panels. Adequate storage areas must be provided for temporary placement of PV modules, structures, and tools prior to installation. The client should also ensure that electrical boards and main switchboards are accessible for PV power reticulation during installation. Clear and unobstructed access is critical for safe execution of all mechanical and electrical activities on site.

5.2 Site Facilities and Utilities

The client shall provide essential on-site facilities such as water supply, electrical power, and sanitary services for use during installation. For systems that include monitoring and data logging, LAN points with internet connectivity must be made available near the inverter or data logger location. Access to the building’s lightning protection system should also be provided to enable secure connection between the PV array’s metal framework and the existing earthing network. These provisions ensure smooth project execution and reduce installation downtime. Coordination between the client and installer is required to finalise utility and facility arrangements before mobilisation.

5.3 Roof Loading and Structural Integrity

It is the client’s responsibility to verify that the roof structure can safely support the weight of the PV system, typically around 0.15 kN/m². Structural drawings and load certifications should be made available to confirm roof strength before installation begins. If necessary, additional reinforcement or structural assessment may be recommended by a qualified engineer. The system design assumes that the roof structure provided by the client meets these loading requirements. Any subsequent modification or alteration to the roof after installation must be communicated to First Solution Group to prevent structural compromise.

6.0 Design Assumptions and Regulatory Compliance

6.1 Design Assumptions

The system design is based on the accuracy of the drawings and information supplied by the client at the time of quotation. It is assumed that there will be no unexpected shading on PV modules beyond what was calculated during the design phase. The distance between the PV modules, inverters, and grid connection point is assumed to be within 20 to 30 metres to maintain voltage efficiency. The grid connection board must have sufficient capacity and available slots for a new circuit breaker connection. These design assumptions are critical to ensuring cost accuracy, system stability, and expected performance outcomes.

6.2 Electrical and Safety Compliance

All PV electrical installations are performed in accordance with SS 638:2018 Code of Practice for Electrical Installations, and EMA’s Technical Requirements for Grid-Connected Solar PV Systems. Safety devices, isolators, and protective relays are sized according to system voltage and current ratings. The entire PV installation is grounded to ensure personnel safety and equipment protection. All live works and terminations are conducted only by Licensed Electrical Workers (LEW PV) registered under EMA. This guarantees full compliance with Singapore’s electrical safety regulations and industry best practices.

6.3 Fire Code and SCDF Audit Compliance

The installation design follows the Singapore Civil Defence Force (SCDF) Fire Code 2023 requirements for rooftop solar PV systems. Fire safety considerations include clear maintenance walkways, emergency disconnection switches, and adequate separation between arrays and parapet walls. The system approval is granted under self-declaration, subject to audit checks by SCDF authorities. Should additional comments or requirements be issued by SCDF, it is the client or building owner’s responsibility to comply accordingly. First Solution Group will provide all necessary technical support and documentation to facilitate these compliance measures.

6.4 Post-DLP Maintenance Option

Upon completion of the Defects Liability Period, clients are encouraged to continue with optional maintenance contracts to safeguard system performance and warranty validity. Our long-term service agreements include ongoing monitoring, periodic inspections, and annual performance analysis. Preventive servicing ensures that energy output remains within design expectations and early signs of degradation are addressed promptly. By maintaining a consistent service record, clients maximise their system’s efficiency and lifespan while ensuring uninterrupted solar generation. Regular maintenance is a vital investment that guarantees long-term energy and financial returns.

Conclusion

Through this comprehensive scope of works, First Solution Group demonstrates its full-service capability in the design, installation, and lifecycle management of solar PV systems in Singapore. From precise engineering design and regulatory submissions to preventive maintenance and long-term performance tracking, we provide end-to-end reliability. Every system we install adheres to national safety and compliance standards, offering clients the assurance of quality and durability. By partnering with us, property owners take a significant step toward energy independence and sustainable operations. Our proven track record and technical excellence continue to make us a trusted leader in solar energy solutions.

Switch to sustainable energy with First Solution Group

Singapore’s trusted expert in grid-connected solar PV systems built for performance and safety. Contact us today.